AMR developer Geek+ has announced the launch of a new technology for smart mixed case palletising, which has been co-developed with warehouse management tools provider WSR Solutions.

The solution combines Geek+ autonomous mobile robots and WSR’s palletising algorithm to assist warehouse operators handle the processing of multiple outbound orders in an more efficient, safe, and flexible way.

Based on real-time demand, Geek+ autonomous mobile robots optimise the movement of ordered goods between the storage area and picking station. At the picking station, WSR’s algorithm supports warehouse operators to stack cases of varying weight and height, in a more optimal way.

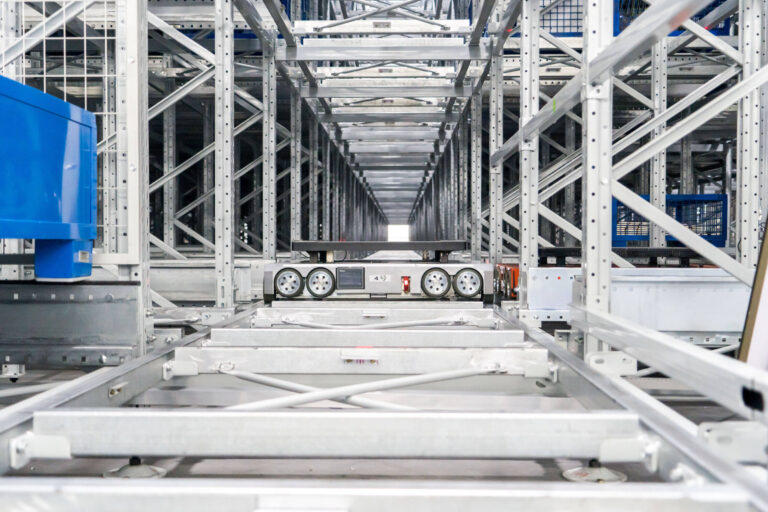

The solution has four key components; a storage area, which contains multiple layers of racking, a buffer area, which case picking area, and loading area.

Lit Fung, Vice President of APAC, UK and the Americas at Geek+ said: “We are thrilled to work together with WSR Solutions to provide a tool that targets every aspect of the outbound logistics process, from how goods are stored and moved around the warehouse to how pallets are stacked, streamlining processes by eliminating the need for re-palletisation, and optimising overall space utilisation.”

Marcel van Schijndel, CEO of WSR Solutions adds: “Together with Geek+ we provide a full framework for the changing market requirements. Innovative mixed palletising solutions that in effect serve one single goal: to optimize the customer’s supply chain with efficient, flexible, and affordable automation solutions.”