Omni-channel fashion logistics operations are looking for easy to install, modular and scalable infrastructure in order to cope with multiple demand peaks and the easing of lockdown restrictions, according to Interroll.

Speaking to Logistics Manager Ben Dietrich, global sales business manager e-commerce and fashion at Interroll, said that omni-channel retailing was experiencing multiple demand peaks, which was posing logistical challenges.

“In the past, only the usual classic seasons like summer or winter have been brought to stores and there were a few peaks only. Nowadays we see partially up to 24 seasons and every social influencer can trigger a peak. Fashion logistics is now seeking to automate as many processes as possible and improve efficiency as well as flexibility wherever possible.”

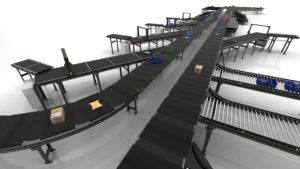

He said that as a result intralogistics that was easy to install, modular and scalable were in high demand.

“We have developed tailor-made process solutions for the issues that are driving the fashion industry in terms of material flow,” Deitrich explained, citing a recent project between BS Handling and ASOS where it optimised sorting process in order to be better prepared for different peaks.

“Up to now, it was mainly larger packaging units that were transported from central warehouses to the stores and back or to the outlet stores themselves. With e-commerce, i.e. direct delivery to the consumer, the demands placed on the supplier’s material flow are changing: it is then necessary to handle a rapidly growing number of individual consignments in ever shorter delivery times, which are also increasingly being packed in plastic bags, so-called polybags.

“Incidentally, this applies equally to shipping and returns, which can account for around 40% to 50% of the flow of goods in this industry,” he added.

Read the Logistics Manager Sector Report on Fashion Supply Chains in our June 2020 issue – available for digital download now!

Deitrich said that only in very few cases are new large-scale infrastructures being set up where operational processes in warehouses and distribution centres then have to be completely changed.

In most cases, he said, users react to the new performance requirements of e-commerce by gradually automating the flow of materials: “The focus is then on innovative solutions that are already technologically proven and can be integrated very easily into existing processes.

“This strategy offers the advantage of achieving the desired increase in performance without running the risk of quasi-disruptively overburdening the own organisation. In addition, the necessary investments can be adapted to the business development as needed.”

![]() Interroll (stand 621) will be exhibited at IntraLogisteX – the UK’s only intralogistics show in 2020 – which takes place on the 29th and 30th September 2020 at the Ricoh Arena, Coventry. Register your interest now at www.intralogistex.co.uk

Interroll (stand 621) will be exhibited at IntraLogisteX – the UK’s only intralogistics show in 2020 – which takes place on the 29th and 30th September 2020 at the Ricoh Arena, Coventry. Register your interest now at www.intralogistex.co.uk