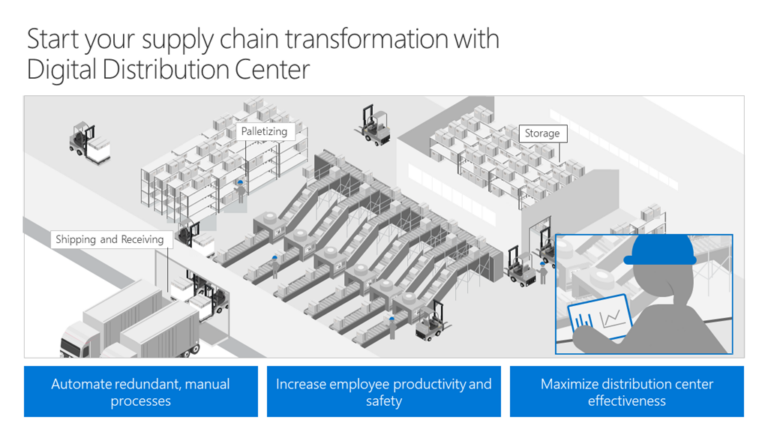

A digital distribution centre solution that uses the internet of things to improve optimisation and increase utilisation of distribution centres for retail, manufacturing, and logistics operations, has been previewed by a partnership between Microsoft, Lenovo and NVIDIA.

The solution uses multi-video stream analytics with artificial intelligence and machine learning inferencing to self-learn, optimise, and scale. Additional releases will include geo-fencing alerts, palletisation, depalletisation, and last-mile sorting.

In a blog on the issue, Bert Van Hoof partner group program manager for Azure IoT at Microsoft, said: “Within the four walls of the distribution centre, picking and packing tasks account for more than 50 per cent of the total labour cost of warehousing operations. Access to labour has become increasingly challenging, particularly in urban centres, and staffing levels shoot up five to ten-times normal levels during the holiday season. Space constraints and difficulty in staffing are pushing companies to look at adopting distribution centre technologies that cut labour costs, optimises the flow of products, and improves productivity and utilisation of these centres.”

In a blog on the issue, Bert Van Hoof partner group program manager for Azure IoT at Microsoft, said: “Within the four walls of the distribution centre, picking and packing tasks account for more than 50 per cent of the total labour cost of warehousing operations. Access to labour has become increasingly challenging, particularly in urban centres, and staffing levels shoot up five to ten-times normal levels during the holiday season. Space constraints and difficulty in staffing are pushing companies to look at adopting distribution centre technologies that cut labour costs, optimises the flow of products, and improves productivity and utilisation of these centres.”

DDC is built with Azure IoT Central, Microsoft’s managed IoT app platform. “The demonstrated solution showed Lenovo hardware, a single SE350 Edge Server, running the Azure IoT Edge runtime with NVIDIA DeepStream to process multiple channels of 1080P/30FPS H265 video streams in real-time, transforming cameras into smart sensors that understand their physical environments and use vision algorithms to find missing products on a shelf or detect damaged goods. Such applications of Azure IoT Edge technology enable customers to quickly and cost effectively deploy retail solutions that optimize their logistics operations,” said Van Hoof.