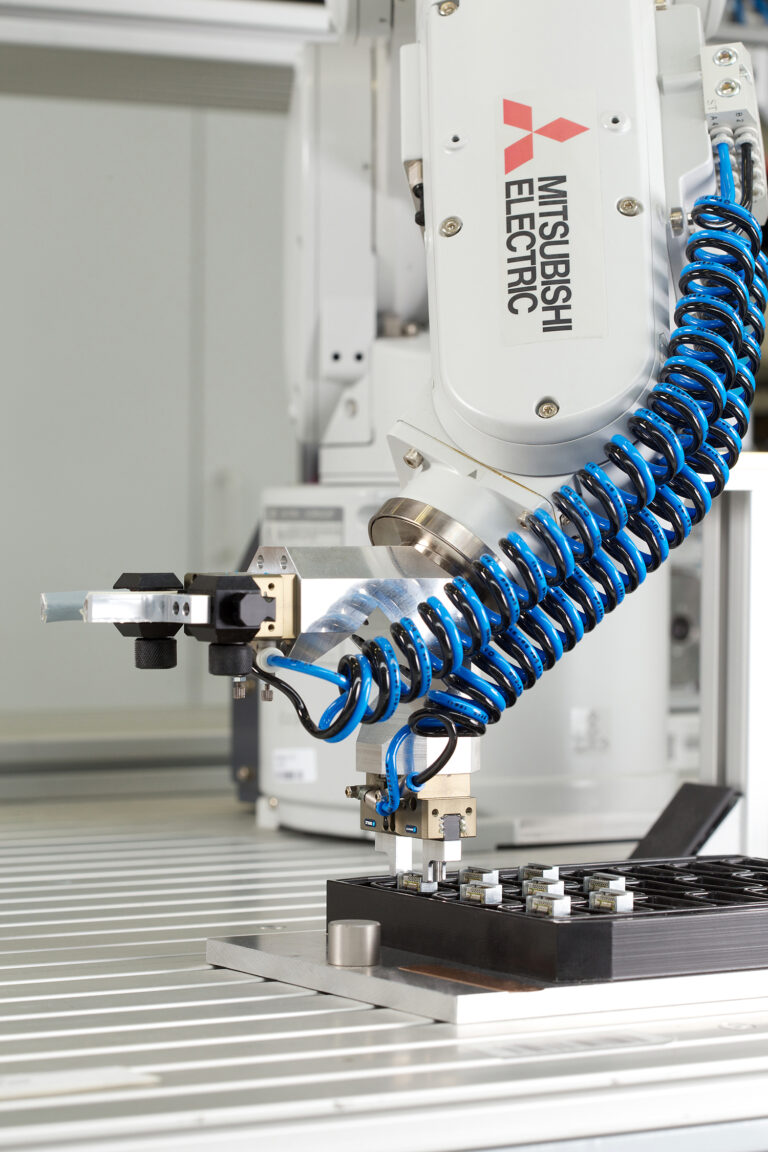

Sensor manufacturer Lenord + Bauer has used an MELFA RV Series robot from Mitsubishi Electric to optimise its manufacturing production cycle in Gladbeck, Germany.

The robot cells have taken over monotonous manual picking tasks on various batch sizes, which allows operators to perform more valuable work elsewhere.

The high level of customisation of L + B’s compact encoders present a challenge for traditional forms of automation, so Mitsubishi Electric was enlisted to provide its MELFA RV Series robots.

Ulrich Marl, head of business production at Lenord + Bauer said: “Besides a compact design, our main requirements included a high level of precision and flexibility – while complying with safety standards, as well as the ability to integrate with our in-house IT systems.”

The required pick-and-place tasks are now carried out to a positional accuracy of ± 20 μm.

The robot also has a safety feature whereby if a person or object encroaches into the safety zone, enters the operating space or collision zone of the robot, a further signal will stop the robot immediately.