Logistics Manager presents the summary report for ‘Robotics in warehousing: the role of robotics in tomorrow’s warehouse’, an Aurora Insights report by senior research associate Shannon Minehan and research assistant Xinchen Li.

To get in touch with the Aurora Insights team, contact research@aurorainsights.co.uk.

Introduction

The warehouse industry is undergoing a period of rapid expansion. This has been fuelled by rising consumer demands resulting from the COVID-19 pandemic and the subsequent rise in both e-commerce and the demand for instant access to goods. To accommodate this growth, warehouses are increasingly adopting robotics and automation technologies. These technologies can be used to improve operations, efficiency, safety, stock management, and rising labour shortages. Specifically, robotics and automation can be used within the warehousing space to minimise or eliminate human involvement, reduce spatial requirements, and enable constant operations which enhance productivity, efficiency, adaptability, and agility (Tutam, 2022; Tubis and Rohman, 2023). Furthermore, robotics and automation can be used to improve environmental, social, and economic sustainability challenges encountered within the warehousing industry.

Background and existing literature

Existing literature identifies a number of challenges within the warehousing industry. The first of these are space constraints. Warehouses must manage their space strategically to maximise efficiency, minimise transportation costs, and meet supply and demand (Cecil-Wright, 1986; Petterson and Segerstedt, 2012). Secondly, warehouses must ensure their stock is organised efficiently. Inefficient stock organisation can lead to higher operating costs and both consumer and employee dissatisfaction (Lambrechts et al., 2021). Another challenge in warehousing is inventory management. If inventory is not managed optimally, warehouses can encounter good surpluses or shortages which can raise costs and decrease profitability (Mason et al., 2003). A final challenge commonly reported in warehouses is a shortage of labour. Warehouses need a sufficient workforce to ensure an ongoing flow of products. Without sufficient staff, warehouses can encounter delays or disruptions which negatively impact profitability (Endo et al., 2021). Each of these challenges can be addressed using robotics and automation solutions.

One such example is the use of drones. Drones are a mobile robotic solution which can be used to improve warehouse operations in a number of ways. Firstly, they can be used for inventory management, particularly in stock taking (Wawrla et al., 2019). Secondly, drones can be used for warehouse surveillance, improving operations and security (Ali et al., 2024) and, thirdly, drones can be used for intralogistics, i.e. moving goods around the warehouse (Wawrla et al., 2019). There are, however, limitations in their application due to several practicality concerns. These include: logistical issues regarding their size and the space through which they are able to move, battery life, reservations about safety, and ethical considerations (Daios et al., 2024; DHL, 2019; Wawrla et al., 2019).

Another example are mobile robots. The two types of mobile robots most commonly used in warehousing are automated guided vehicles (AGVs) and autonomous mobile robots (AMRs). These can be employed to alleviate repetitive and tedious tasks, and transport, pick, and replenish goods (Pasparakis et al., 2021; Winkelhaus & Grosse, 2022).

These mobile technologies enable safe human-robot collaboration as they do not operate within a separate work cell. Collaborative robots (cobots), such as these, are therefore popular in warehouses as they allow for direct collaboration between robots and humans. Further, they are designed and constructed to react to human input and requests, while also making necessary adjustments (Pauliková et al., 2021; Calitz et al., 2017; Sheridan, 2016). This means cobots are more flexible in their application than traditional industrial robots.

AI is also becoming more regularly used in the warehouse space. AI systems are capable of learning the optimal way to handle different products (Endo et al., 2021). These solutions have a range of applications in the warehouse space. In conjunction with other software solutions, AI systems can be used to improve hardware by increasing robots’ ability to respond to dynamic changes in environment through continuous learning. They can also be applied to understand sales trends and forecast demand to support data-driven storage planning and replenishment management workflows (Mahroof, 2019).

Internet of Things (IoT) technologies also have warehouse applications. IoT can be used to interconnect diverse warehouse devices, which allows for better data collection, more efficient monitoring operations, and the establishment of a real-time logistics network (Buntak et al., 2021).

One such example of IoT technology’s usefulness in warehousing is the application of digital twins to manage warehouse operations. Digital twins can facilitate the selection of equipment, operation strategy, and overall warehouse structure, sizing, and dimensioning in warehouses, as well as departmental layouts (Leng et al., 2021). This can significantly advance warehouse operations.

Integration systems can also be advantageous to warehouse operations. By integrating hardware and software technologies, warehouses can streamline automation operations and improve decision making processes (Fedotov et al., 2020; Min, 2022).

We identify several impacts of increasing the use of robotics and automation in warehousing in existing literature. The first of these is increased efficiency. A number of studies identified a positive relationship between the use of robotics and efficiency (Jabbar et al., 2018; Van Geest et al., 2021; Berkers et al., 2023). A caveat of this increased efficiency, however, is that as the presence of robots rises, warehouses may encounter challenges relating to task allocation and real-time route planning.

Warehouses managers must also consider costs in the application of robotics and automation. While these technologies can have long-term cost savings, they can be expensive to procure and implement, with breakdowns in the technology leading to substantial maintenance and repair costs (Kamali, 2019). Further, cyber security problems and glitches have the potential to disrupt processes, which can slow down operations and negatively affect profitability (Kamali, 2019).

Using robotics in warehouses can also have environmental implications, principally through the optimisation of resources via automation. Robotics and automation can reduce the production of CO2 emissions by reducing the need for on-site transportation (Sadeghi et al., 2023). Furthermore, robots do not require ambient temperature control or lighting, which can likewise reduce energy consumption and thus adverse environmental impacts while also bringing down operating costs (Anandan, 2019; MCRI Marketing, 2013).

Robotics and automation can also improve warehouses’ operational reliability by reducing reliance on manual labour and processes. Presently, traditional warehouse management relies on human input, which can be error-prone and inaccurate. In fact, human input is responsible for 80% of inaccurate information in warehousing (Li et al. 2011). This can lead to uncertainty and complexity in warehouse logistics (Li et al. 2011; Zhou et al., 2017).

Finally, the impact of robotics and automation adoption on jobs is heavily debated in existing literature. On one hand, many argue that the adoption of robots will displace workers both directly and indirectly. Directly, warehouse workers, particularly lower-skilled workers, will be replaced with more efficient robots that require no breaks or training. Indirectly, robots may also lead to increased workloads and a higher pace of work, potentially increasing employee turnover and the emergence of health risks associated with overwork (Cucca and Royuela, 2024; Gutelius and Theodore, 2019; Wawrla et al., 2019). On the other hand, existing literature has also highlighted the potential for robots to free up time for low-skilled workers, giving them the chance to upskill and find higher level jobs. Further, as technology evolves, new jobs will be created offering new opportunities to those who would initially be displaced (Hu et al., 2023; Jaller et al., 2023).

Data

We manually constructed a novel dataset from interviews conducted by Akabo Media with businesses operating in the warehousing industry and implementing robotics and automation solutions into their systems and operations. From each case study, we manually collected information on the challenges each project sought to overcome, the solutions implemented, technologies used, features required, and benefits reaped.

Overall, our sample consists of 33 projects involving 61 companies. On average, just over two companies were involved in each project. Approximately 46% of companies in our sample operated as end-users, while 54% operated as suppliers. Around 48% of companies within our sample were large companies with more than 1,000 employees. Some 82% of companies in our sample were headquartered in the United Kingdom. Nearly 30% of our sample operated in the logistics industry, with the next most common industries represented being manufacturing (18%) and retail (18%).

Trends in challenges

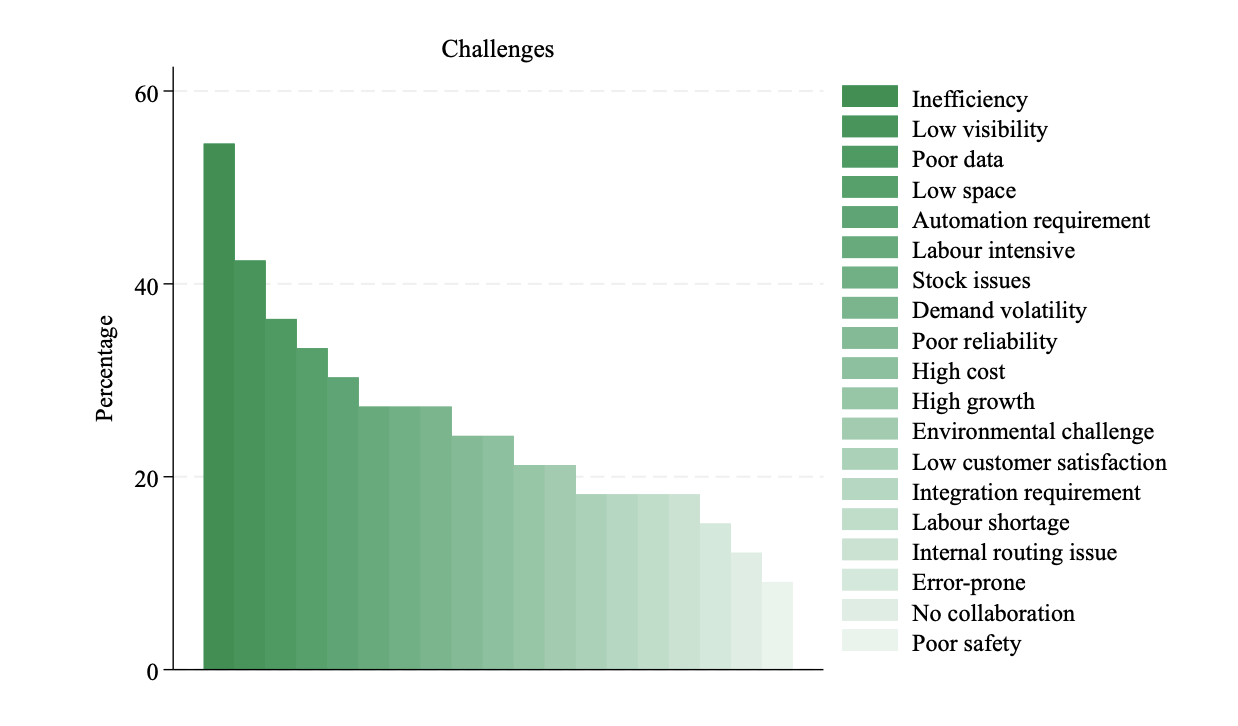

We identified five key challenges within our sample:

- More than half (55%) of the sample reported inefficiency as a challenge within their warehouses. Inefficiency can lead to poor and non-optimal operations, decreasing the speed goods can move through the supply chain and thus raising costs and decreasing profitability.

- Of the sample, 42% reported challenges of low visibility. This can impact a warehouse’s ability to locate products quickly and accurately which in turn can disrupt supply chains and make them unreliable.

- Over a third (36%) of the sample reported challenges regarding poor or low-quality data collection. High quality data is important for warehouses to collect as it is critical for increasing the accuracy, visibility, and thus efficiency of inventory management and stock taking processes.

- A third of our sample struggled with space constraints. When warehousing space is not used efficiently, it can lead to increased handling time, reduced productivity, and thus reduced profitability.

- Around 30% of our sample reported challenges that required automation. Many warehouses reported manual processes that were time-consuming and monotonous. These can lead to inaccuracy and inefficiency, and can reduce profitability.

Trends in technologies and solutions

We identified several trends in the solutions and technologies applied to address these challenges. More than half of the sample (52%) implemented software solutions such as enterprise resource planning systems (ERPs), control towers, and warehouse management systems (WMS) to address challenges of inefficiency. These systems increase visibility, which in turn improve accuracy, safety, and efficiency. Similarly, 52% of the sample introduced automation into their supply chains. This resolved issues of high costs, inefficiency, and time-consuming manual processes. Data analytics solutions were used in 42% of case-studies to identify and address existing and potential challenges within warehouses, while two fifths of the sample introduced robots into their warehouses, using the technology to improve safety issues, fulfil automation requirements, increase operation accuracy, and improve efficiency. Finally, nearly 40% of the sample used AI in their robotics and automation solutions to both identify challenges or instruct other technologies.

Trends in benefits

Companies experienced a range of benefits from the implementation of robotics and automation solutions. More than 90% of our sample improved the efficiency with which they operated. Furthermore, more than three quarters of the sample improved warehouse visibility, 61% improved accuracy, 52% began collecting more or better-quality data, and 48% improved customer satisfaction. Each of these benefits improved operations, decreased costs, and increased performance and profit.

Conclusion

In conclusion, the applications for robotics and automation technologies within the warehousing industry continue to grow. Robotics and automation can be used to improve efficiency, accuracy, and safety while also reducing costs and increasing performance. Our paper finds multiple applications and benefits for their use in warehouses.

Click here to pre-order the full report.

About Aurora Insights

Aurora Insights is an intelligence and consulting division of the UK’s leading B2B events and publishing company, Akabo Media. Launched in 2023, the business provides research reports and bespoke research offerings supported by ever-growing archives of data collected through the host of events, conferences and exhibitions run by Akabo Media.

To learn more, visit the Aurora Insights website.