There’s no way around the fact that Autonomous Mobile Robots (AMR) are the most exciting development in logistics for a long time.

And with good reason.

- They are no longer an immature product, the benefits and ROI are real.

- They are no longer the ‘expensive, unobtainable’ option. Costs are down. They really could be within your budget.

- They work with humans, they don’t replace them. Making your workforce stronger.

- There is more than just 1 type of AMR. They are flexible and can suit your operation, no matter how bespoke.

Autonomous Mobile Robots (AMR) are used to fill some of the more labour-intensive functions in a warehouse. Such as:

- Walking to different picking points

- Pushing cages/trollies

- Finding the correct and most efficient picking path

- Picking up heavy items

All of this leads to massive gains in:

- Efficiency

- Capacity

- Productivity

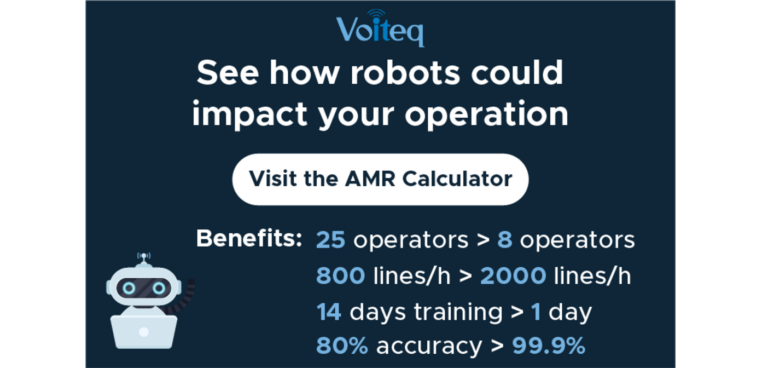

There’s no time to waste, we can show you how much you could be saving in a few clicks. Here are some real stats from our implementations.

Headcount for Picking & Sorting:

25 > 8

Warehouse Throughput:

800 lines/h > 2000 lines/h

Operator Training Time:

2 weeks > 1 day

Accuracy Level:

80-90% > 99.99%

Click here to instantly calculate the impact and savings AMR could have on your warehouse: