The 15th International Advanced Robot and Simulation Technology Competition took place online, with students from the UK, USA, Germany, Australia, South Korea, and elsewhere, joining Chinese students in a competition to design a new smart factory.

Over 7,000 students from around the world took part, using simulation software to create smart factory projects.

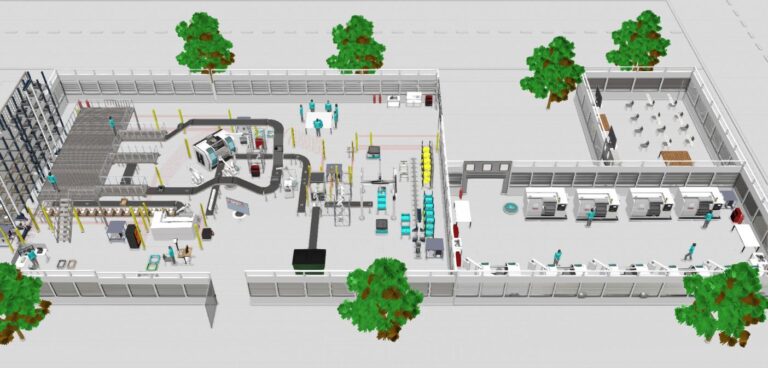

One of the winning teams came from the North China Institute of Science and Technology. This team designed a smart factory that manufactures impellers, which are typically used in pumps for turbomachines. Their design included the use of 5G technology to collect operational data and monitor the factory’s production process as well as mounted robots and automated guided vehicles (AGVs).

The simulation solution used for the projects was developed by Artificial Intelligence of Things (AIoT) service provider MeiCloud using technology from Visual Components. Umair Ejaz, Senior Manager at Visual Components, said: “The goal was to promote simulation technology and upskill the students to solve real-life industrial challenges.

“Participants used our simulation software to create smart factory projects and help drive their understanding of digital twins and virtual commissioning technologies.

“We were immensely proud of the fact that Visual Components’ software was exclusively utilised by students to fully familiarise themselves with state-of-the-art simulation tools.”

Ejaz described the competition as “a highly valuable exercise as the skills learnt by students during the competition can be applied when they enter the workplace following their studies”.

Logistics Manager spoke with Ejaz about how simulation technology and digital twins can be used to improve manufacturing processes in the future.

He said: “Digital twins provide real-time insight of production systems, so manufacturers can discover how their resources are being used and tweak them to be more efficient.

“AGVs on the factory floor are a great example. Too many in the building can lead to traffic deadlocks and inefficiencies when following a designated path to their destination.

“Also, if there are a number of product variants that are causing complexity on the production line, this technology can provide oversight to help drive more structured processes and improve quality at the same time.

“Predictive maintenance is also a valuable benefit of digital twins. Digital twins can monitor and analyse data from equipment in real-time, enabling predictive maintenance, to prevent any breakdowns and avoid detrimental downtime.”

Ejaz also alluded to the benefits of digital twin technology for health and safety as well as for sharing knowledge with different teams around the world.

Visual Components exhibited at the co-located IntraLogisteX and Robotics and Automation exhibitions in March 2023. To find out more about next year’s event, visit the IntraLogisteX or Robotics and Automation website!